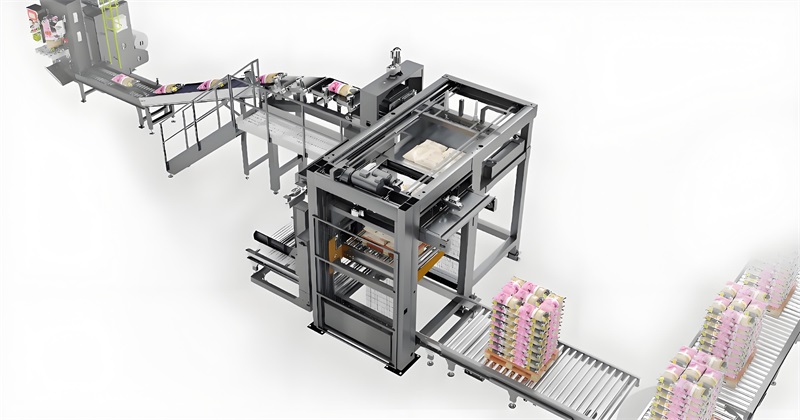

In large-scale manufacturing, the palletizing stage plays a crucial role in ensuring that finished goods are prepared safely and efficiently for storage, transportation, and downstream logistics. As production lines become increasingly automated, companies are looking for machines that can deliver high throughput, precise stacking, and minimal manual intervention. The High-Level Palletizer is one such solution—designed specifically to handle stable bags or packages at high speeds, forming accurate layers and delivering consistent pallet quality.

This article explores how high-level palletizers work, what makes them different from low-level systems, and why industries with high production volumes increasingly rely on them. Drawing from the engineering expertise of Dostar Packing, a company with over two decades of experience in automated packaging systems, we take a closer look at the advantages and practical applications of this technology.

1. What Is a High-Level Palletizer?

A high-level palletizer is a machine used to stack bags, cartons, or packaged goods onto pallets at elevated infeed heights. As the name suggests, product entry occurs at a high level, allowing the machine to achieve:

-

Faster cycle times

-

Smooth, continuous material flow

-

Reduced lifting energy

-

Stable layer formation

These machines are ideal for operations where packaging moves at high speeds and where each bag or item has a consistent shape designed for stackability.

High-level palletizers are used in industries such as:

-

Chemical and fertilizer production

-

Food and grain processing

-

Animal feed manufacturing

-

Building materials

-

Plastics and resins

-

Industrial powders and granules

In these settings, production lines often run continuously, making automation essential for achieving throughput goals and minimizing downtime.

2. Key Components and Workflow of a High-Level Palletizer

Although different models may vary in design, most high-level palletizers share a similar structural and operational framework.

(1) Infeed Mechanism

Products are delivered onto a conveyor system, often through the main packaging line. This infeed stage ensures smooth product transfer and consistent spacing.

(2) Sorting and Orientation Technologies

Depending on the product, various orientation mechanisms may be employed:

-

Belt turners

-

Pressing systems

-

Side pushers

-

Rollers or diverters

These ensure that each bag or package reaches the layer-forming area in the correct orientation according to preset patterns.

(3) Layer-Forming Mechanism

This is the core of the machine. A manipulator, grid mechanism, or pusher arranges the products into a layer pattern. Patterns are determined by:

-

Product size

-

Pallet dimensions

-

Required load height

-

Stability requirements

-

Storage or shipping configurations

Algorithms and sensors guide the movement to ensure accuracy.

(4) Transfer Mechanism

Once a layer is formed, it is transferred smoothly onto the pallet:

-

Using sliding plates

-

Push arms

-

Fork-style lifting mechanisms

This process repeats until the stack reaches the required height.

(5) Pallet Discharge

Completed pallets are discharged onto a conveyor or moved to a pallet wrapping system for stabilization.

This structured process ensures that every product is placed precisely and efficiently.

3. The Role of Advanced Technology in High-Level Palletizing

Modern palletizers integrate multiple layers of automation to enhance accuracy and reduce errors.

PLC Control Systems

Programmable Logic Controllers (PLC) serve as the operational core, allowing:

-

Pattern programming

-

Speed adjustments

-

Production monitoring

-

Real-time troubleshooting

Sensor Systems

Sensors detect:

-

Product presence

-

Height levels

-

Layer alignment

-

Conveyor flow

This removes manual checks and reduces the risk of product misplacement.

Optional Vision Systems

For advanced applications, vision systems can verify product positions, detect irregular bags, and optimize layer composition automatically.

These integrated technologies enhance reliability and ensure stable, repeatable palletizing performance across shifts.

4. Why Choose a High-Level Palletizer Instead of Other Types?

High-level palletizers have several operational advantages over low-level or robotic alternatives.

Higher Palletizing Speeds

Because the infeed is at a high level, product movement requires fewer elevation changes, enabling faster cycles.

Stable Layer Formation

The layer-forming surface offers more control over pattern accuracy, especially for:

-

Rectangular bags

-

Flat goods

-

Consistent weight products

Lower Energy Consumption Compared to Robotic Systems

Mechanical systems often consume less energy and require simpler maintenance than robotic palletizers.

Ability to Handle High Production Volumes

Their robust structure makes them suitable for continuous heavy-duty operation.

These advantages make high-level palletizers especially suitable for industries with large output requirements.

5. Designed for Bags and Packages With Defined Shapes

The system works best when handling products that maintain structural integrity, such as:

-

Woven bags

-

Valve bags

-

PE or laminated bags

-

Carton boxes

Stable bag shape improves layer pattern accuracy and overall pallet stability. For industries with high-speed filling and bagging machines, integrating a high-level palletizer ensures that the flow from filling to palletizing remains uninterrupted.

6. Efficiency and Space Savings Through Optimized Patterns

The ability to create tightly aligned layers directly contributes to warehouse efficiency. Well-formed pallets:

-

Reduce the risk of toppling

-

Allow higher stacking in storage

-

Improve transport safety

-

Minimize wasted pallet space

Pattern algorithms consider pallet dimensions and load requirements to maximize every layer. Over time, this contributes to cost savings throughout logistics operations.

7. Integrated Into Automated Packaging Lines by Dostar Packing

Since 2004, Dostar Packing has specialized in developing automatic packaging production lines, providing comprehensive systems from product feeding to pallet wrapping. The high-level palletizer is a key part of the company’s full-automation solutions.

Dostar’s capabilities include:

-

High-accuracy filling machines

-

FFS (Form-Fill-Seal) bagging machines

-

Open-mouth bag packing machines

-

Vacuum packing solutions

-

Conveyor and palletizer systems

-

Pallet wrapping and load stabilization solutions

With a strong engineering team, Dostar ensures each system is designed to integrate seamlessly into the customer’s existing layout and production flow.

8. Reliability Through Manufacturing Expertise and After-Sales Support

Dostar prioritizes:

-

Stable performance

-

Consistent output

-

High system uptime

-

Long-term reliability

The company also emphasizes its service philosophy: creating value for customers and enhancing employee and societal well-being. This reflects a long-term commitment to product support, training, maintenance, and customized engineering solutions.

9. Applications Across Multiple Industries

High-level palletizers are widely used in industries such as:

-

Chemical and petrochemical

-

Fertilizer production

-

Grain and food processing

-

Building materials

-

Mining and minerals

-

Plastic pellets and resins

-

Animal feed manufacturing

Any sector that deals with high-volume bagging or regular-sized packages benefits from the speed and uniformity a high-level palletizer delivers.

Conclusion

The High-Level Palletizer offers manufacturers a fast, accurate, and stable solution for organizing finished products into palletized loads. With its advanced mechanical structure, PLC-based control system, and automated layer-forming technology, it significantly improves productivity and pallet quality. As part of Dostar Packing’s full packaging production line solutions, the palletizer helps businesses increase automation, reduce labor costs, and achieve consistent output across large-scale operations.

www.dostar-pack.com

Dostar Packing