In numerous industrial sectors, from chemical processing to power generation, the efficiency and reliability of heat exchangers and reactors are paramount. One crucial component that contributes significantly to the durability and performance of these systems is the tantalum lined tube sheet. Tantalum, known for its excellent resistance to corrosion and high-temperature stability, is increasingly being used in specialized applications that require both chemical resistance and mechanical strength. The tantalum lined tube sheet is an advanced engineering solution that enhances the overall lifespan and reliability of heat exchangers and reactors in demanding environments. This article Qiwei delves into the applications of tantalum lined tube sheets.

What is the Tantalum Lined Tube Sheet?

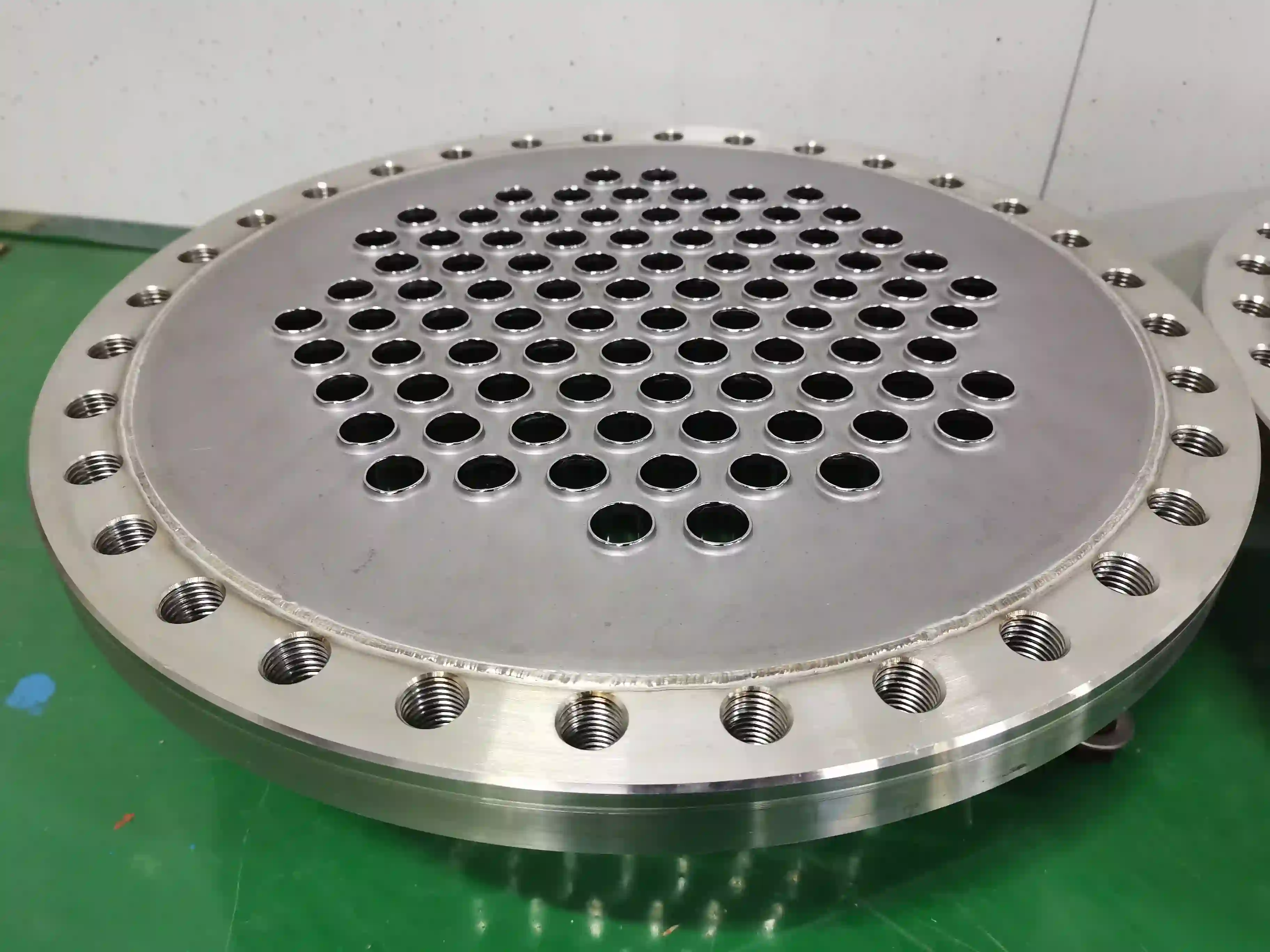

A tantalum lined tube sheet is a type of tube sheet—an essential component in heat exchangers, reactors, and similar systems—that is coated or lined with a layer of tantalum metal. The tube sheet itself serves as a structural element to hold the tubes in place and facilitate the flow of fluids or gases through the system. Tantalum, known for its exceptional corrosion resistance, is used to line the tube sheet in environments where traditional materials like steel or aluminum would fail due to exposure to aggressive chemicals or high temperatures. The role of the tube sheet in heat exchangers and reactors cannot be understated, as it plays a critical role in preventing leaks and maintaining structural integrity. By lining these tube sheets with tantalum, industries ensure a higher level of protection for their systems against the aggressive nature of the substances involved.

Tantalum's remarkable resistance to corrosion, even in the presence of concentrated acids such as sulfuric acid or hydrochloric acid, makes it a material of choice for industries that operate in highly corrosive environments. The tantalum lined tube sheet provides an additional layer of protection, ensuring the efficient operation of systems over extended periods.

Applications of Tantalum Lined Tube Sheets

Tantalum lined tube sheets are utilized in a variety of critical industrial applications, where their corrosion resistance, durability, and high-temperature stability offer distinct advantages over conventional materials. Below are some of the primary industries and applications where tantalum lined tube sheets are indispensable.

1. Chemical Processing

The chemical industry often deals with highly corrosive substances, such as acids, alkalis, and solvents. In chemical reactors, heat exchangers, and condensers, tantalum lined tube sheets play a crucial role in ensuring that the materials used can withstand the aggressive nature of the chemicals involved. Chemical reactors, particularly those handling strong acids, alkalis, and solvents, require materials that can withstand corrosion and maintain structural integrity. Traditional materials such as carbon steel and stainless steel may corrode or degrade over time when exposed to these substances. Tantalum lined tube sheets ensure the longevity and performance of heat exchangers and reactors by offering enhanced resistance to corrosion and preventing leaks or equipment failure. In particular, tantalum lined tube sheets are ideal for use in the production of fertilizers, petrochemicals, and specialty chemicals, where they are used to separate and support the tubes in heat exchangers. Their corrosion resistance allows these systems to operate efficiently over long periods without the risk of failure due to corrosion or erosion.

2. Power Generation

Power plants, particularly those in industries such as nuclear, solar, and petrochemical, use heat exchangers to regulate the temperature of fluids and gases during the energy generation process. These systems are often exposed to extreme temperatures, pressure, and corrosive substances, making it essential to use materials that can maintain integrity under such demanding conditions. In power plants, tantalum lined tube sheets serve to improve the reliability of heat exchangers and reactors by offering resistance to high-temperature corrosion. The high melting point and exceptional stability of tantalum ensure that heat exchangers continue to perform optimally even under conditions of thermal cycling and thermal shock. The material also helps prevent degradation from exposure to various chemicals, ensuring that heat exchangers function efficiently for extended periods. Moreover, the tantalum lined tube sheet enhances the structural integrity of these systems, preventing leaks and failures. This is particularly important in industries such as nuclear power generation, where failure could lead to significant safety hazards.

3. Petrochemical Industry

In the petrochemical industry, tantalum lined tube sheets are utilized in reactors, heat exchangers, and distillation columns that process petroleum products. These systems often come into contact with highly corrosive substances, such as sulfuric acid, hydrogen fluoride, and other aggressive chemicals, as well as high temperatures and pressures. Petrochemical plants require equipment that can endure constant exposure to aggressive substances. Tantalum lined tube sheets are used to provide long-term protection in such environments. Tantalum's resistance to sulfuric acid, hydrogen chloride, and other corrosive compounds ensures that equipment remains operational for extended periods without frequent maintenance or replacements. This ultimately lowers operational costs and increases overall plant efficiency. Tantalum's unique properties also allow petrochemical systems to operate at higher temperatures and pressures, maximizing production output while minimizing the risk of system failure.

4. Pharmaceutical and Food Processing

In pharmaceutical and food processing applications, maintaining hygiene and the integrity of processed materials is critical. Tantalum lined tube sheets offer the necessary corrosion resistance and durability to handle a wide range of chemical agents and temperatures, ensuring that products are processed in safe and sterile environments. The pharmaceutical and food processing industries often face the challenge of dealing with aggressive chemicals, extreme temperatures, and the need for sterile conditions. Tantalum lined tube sheets not only provide resistance to corrosion but also help maintain the quality of the final product by preventing contamination. Their high mechanical strength ensures that reactors and heat exchangers remain intact, even in the face of rigorous cleaning processes or high pressures. In addition to their chemical and temperature resistance, tantalum lined tube sheets also contribute to improving the efficiency of these systems by reducing the risk of corrosion-related downtime, ensuring a more stable and reliable operation.

Tantalum lined tube sheets are an invaluable component in many industrial applications, particularly those involving high temperatures and corrosive substances. The unique properties of tantalum, including its corrosion resistance, high-temperature stability, and mechanical strength, make it an ideal choice for enhancing the durability and performance of heat exchangers, reactors, and other critical systems in industries such as chemical processing, power generation, petrochemicals, and pharmaceuticals. By incorporating tantalum lined tube sheets into their systems, industries can enjoy longer equipment lifespans, reduced maintenance costs, and improved operational efficiency. The superior performance of tantalum ensures that systems operate smoothly under even the most demanding conditions, making it a cornerstone material in industries that rely on reliability and efficiency.

https://www.tnztn.com/Tantalum-Lined-Tube-sheet.html

www.tnztn.com

Wuxi Qiwei Nonferrous Technology Co., Ltd.